Innovation

Working with nature, not against it

Research and Development

At AgBiTech we have a robust and dynamic research program dedicated to the ongoing development of cutting-edge biological insect control solutions for growers. Since 2016, we have successfully introduced five new products, demonstrating our commitment to continuous innovation. Simultaneously, we relentlessly strive to enhance the efficiency of our existing products and optimize our manufacturing system. AgBiTech’s laboratories are located in Toowoomba Australia, Dallas Fort Worth USA and Goiânia, Brazil.

Our products have been extensively tested and proven effective in controlling pests across diverse scenarios. We firmly believe in the global applicability of NPVs against new pest targets, and we are actively working towards achieving that goal.

With an unwavering focus on expanding the reach and impact of our solutions, AgBiTech's research program remains at the forefront of the industry, continuously pushing the boundaries of biological insect control for the benefit of growers worldwide.

Novel Mode of Action

Working with Nature, not against it

While caterpillars have developed resistance to most chemical insecticides and now also to some genetically modified (GM) crops, they have not done so with their co-evolved naturally occurring viruses. These viruses have virtually no effect on any other species which makes them incredibly safe to beneficial insects, the environment and most importantly, to people.

Paradigm Shifting Innovation with Semiochemicals

Controlling Moths Before Egg-Laying

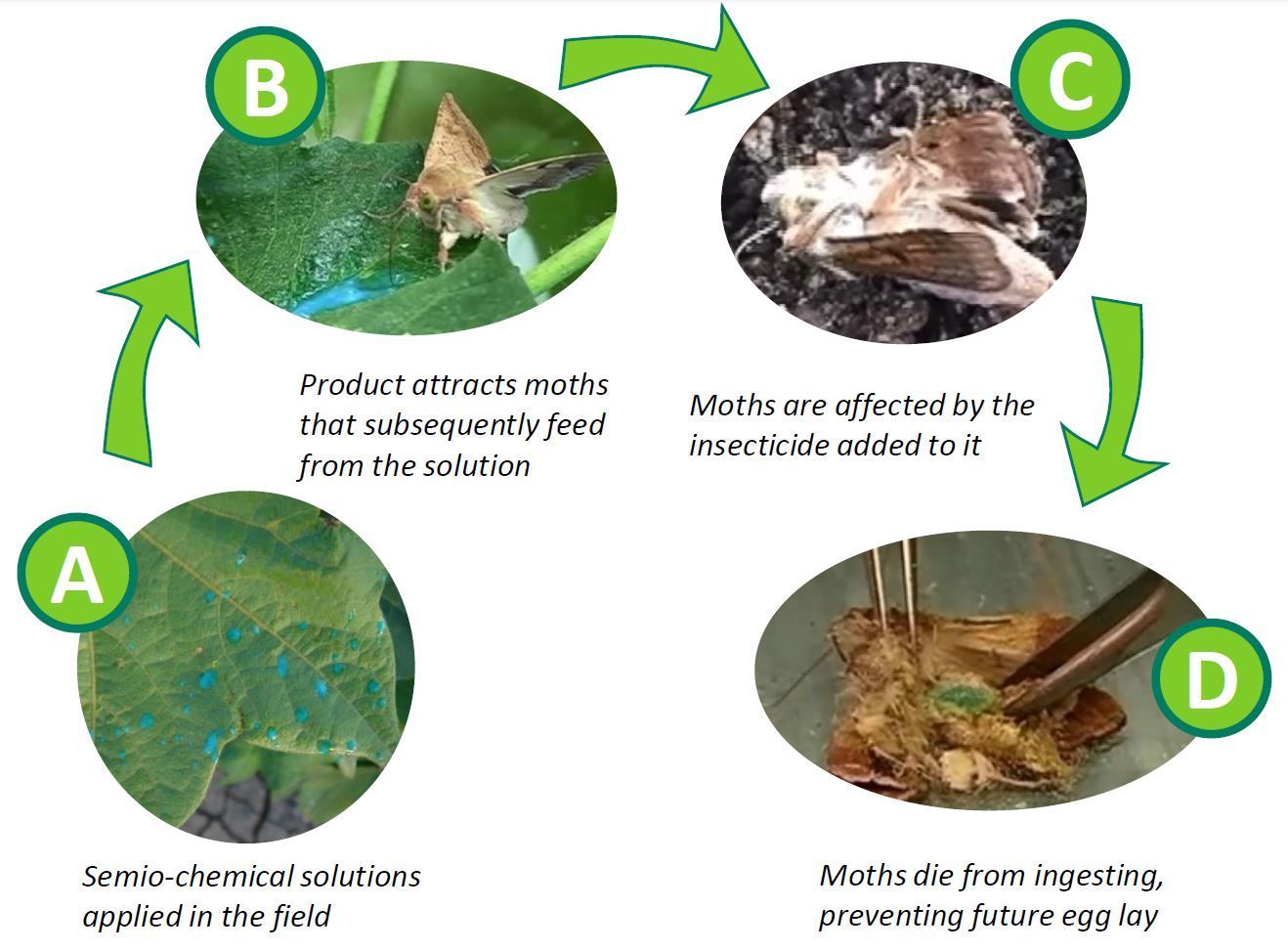

AgBiTech is completely changing caterpillar/worm management by controlling them even before they are born.

Our Semiochemical solutions are a mixture of carefully selected plant volatiles, especially formulated to attract moths of the Noctuidae species.

AgBiTech has developed proprietary formulations with components mixed in optimal ratios (patented), resulting in highly attractive compounds for moths in the field.

Unlike pheromones that only attract males, ABT proprietary blends target newly emerged and copulated female moths.

The mixture is combined with an insecticide to both attract and kill moths.

Our Semiochemical solutions are already a great success in Australia and are growing in Brazil and being introduced in Argentina.

Semiochemicals Mode of Action

Production

How are NPVs produced?

The production of NPVs take place inside the caterpillar pest. This process involves the mass rearing of huge numbers of caterpillars in a climate-controlled environment, and infecting them with a small amount of NPV. AgBiTech’s manufacturing facility in Fort Worth, Texas, USA, has proprietary technologies that enable the production, maintenance, and infection of millions of caterpillars every day. The amplified OBs are subsequently harvested from the dead caterpillars through a process of washing and centrifugation, and eventually formulated into a concentrated virus product. AgBiTech maintains formulation and packaging capabilities in the USA, Australia, and Brazil for its NPV products and the adjuvants Optimol and Magnet/Chamariz.

Quality control of AgBiTech’s NPV products

Each product that we produce undergoes rigorous quality checks and all of our products leave the factory with a Certificate of Analysis to give our customers peace of mind.

List of services

-

OB countsList Item 1

The OB count defines the level of active viral particles in the product. AgBiTech undertakes OB counts on every batch of product to ensure product quality and consistency.

-

Potency bioassaysList Item 2

AgBiTech compares every batch of product to a specific reference virus sample of known virulence to ensure product quality and consistency.

-

Contaminant levelsList Item 3

The production of NPV is a biological process involving the mass rearing and infection of huge numbers of caterpillars. Thus, this process has the potential to introduce microbial contaminants into the product. AgBiTech’s manufacturing process is designed to minimize microbial contamination. In addition, every batch of product undergoes independent laboratory testing to ensure that the final product meets food standards with respect to microbial contamination.

-

Storage and transportList Item 4

NPV is stable for years when stored at temperatures of 4°C or lower. Extended periods of time at higher temperatures can result in virus degradation and loss of product potency. To ensure that NPV is readily available and reaches growers in perfect condition AgBiTech has established a large cold depot and delivery network.